Jason Molding are strongly committed to quality and quality control systems are accredited to ISO: 9001. The document control system goes through all the production & quality control inspection processes. Jason Molding have independent quality control department who controls every plastic mold and plastic molding parts quality inspection step from incoming material, production process of mold making and plastic molding, assembly, packing, as well as cargo shipment.

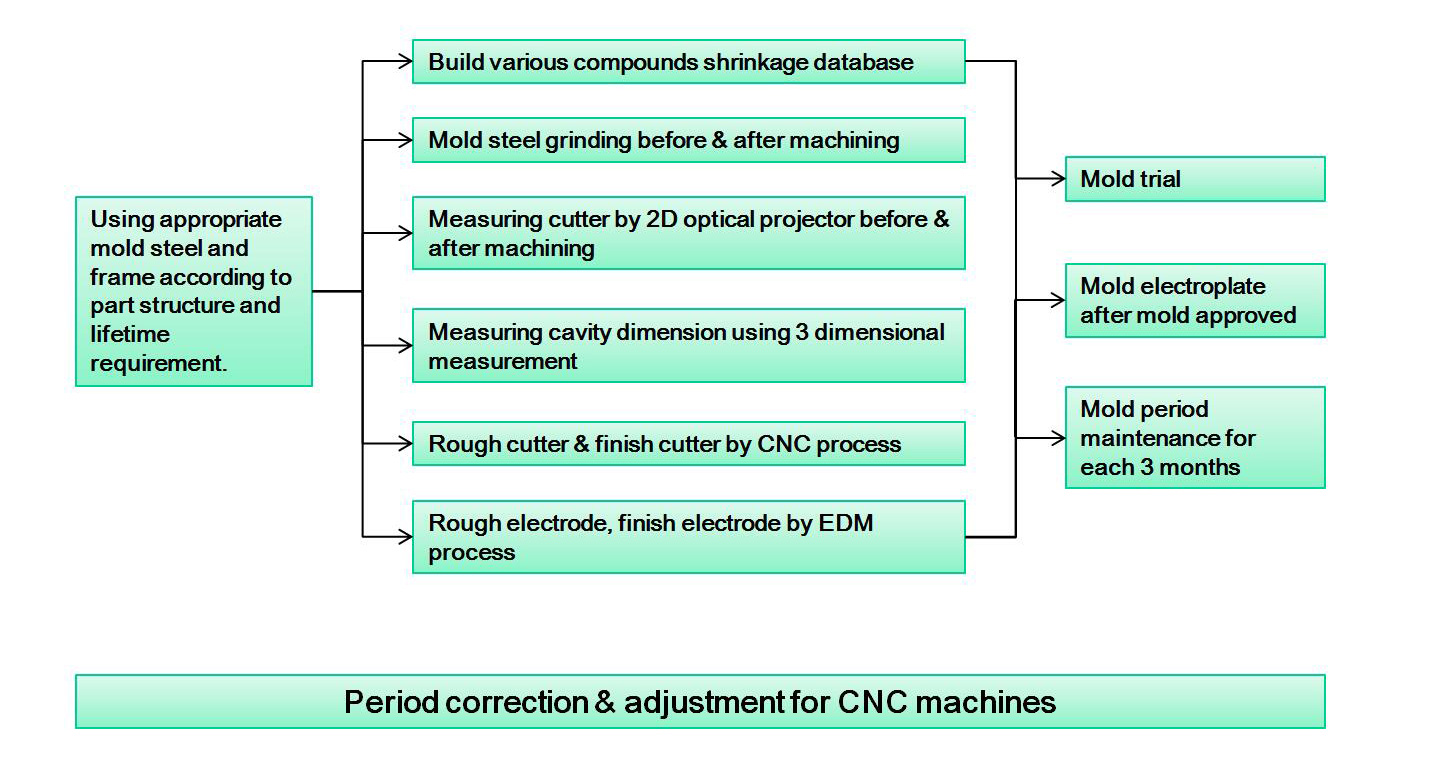

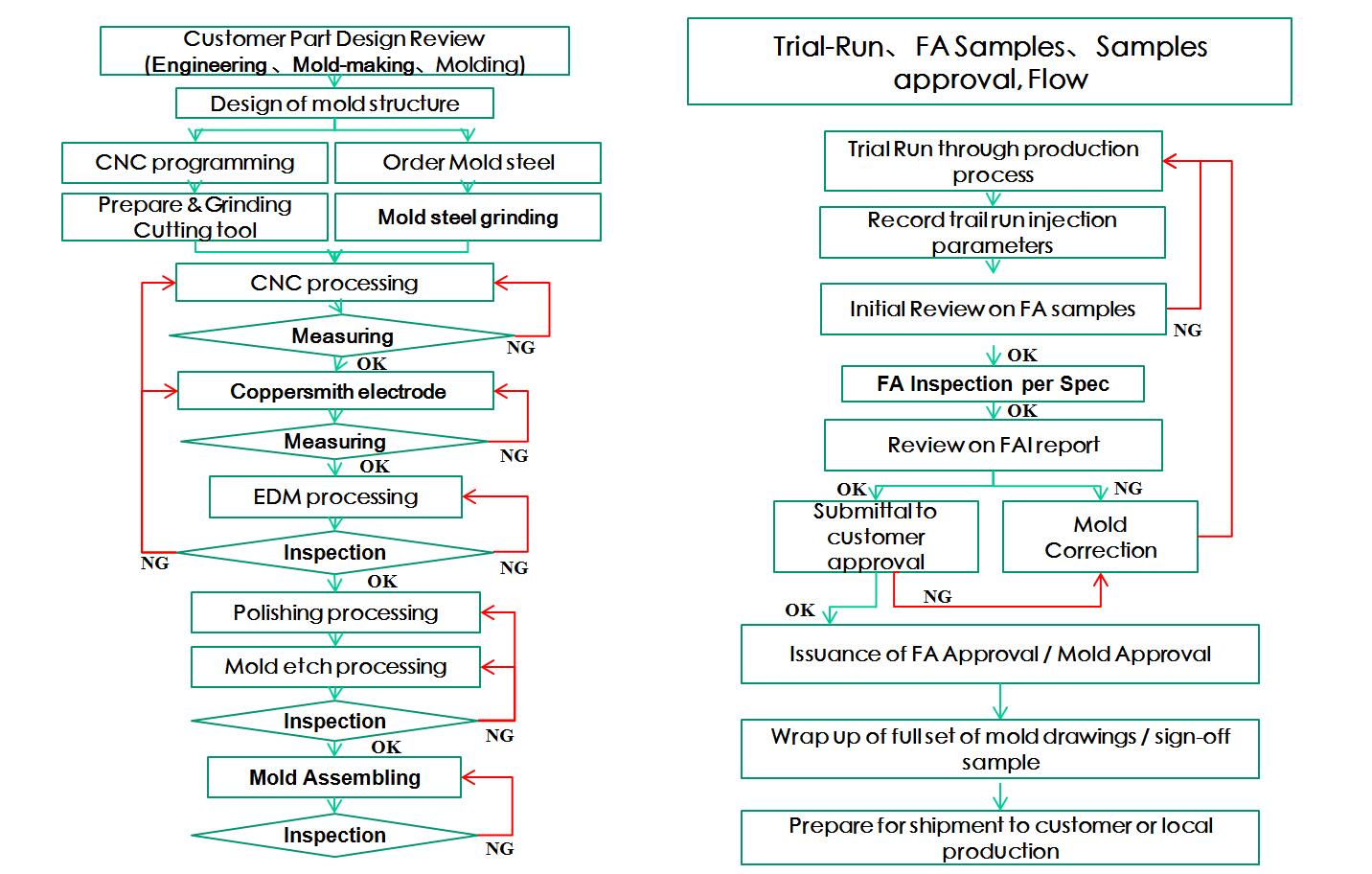

Mold quality is the foundation of our success, 90% of our new injection molds only take 1 time or 2 times testing before we put them into mass production or send to oversea customers. From materials incoming to finished work piece before mold assembly, we have a fully implemented quality control process to ensure lower re-work rate, lower wastage, high efficient and short delivery term. From first article inspection to process capabilities study (PPAP), we guarantee production is stable and correctness. All mold steel/resin we used is strictly following customers’ quality requirements, steel purchased certificates and property specification of plastic raw materials are always available.

We have established quality evaluation program for each process to assure our customer the best quality products and most professional service. We own a full set of advanced measuring and testing equipment, our can provide a series of testing reports upon customer’s request at any time such as CPK, FAI, PPAP, PFMEA and so on.

Mold-making And Sample Approval Quality Control

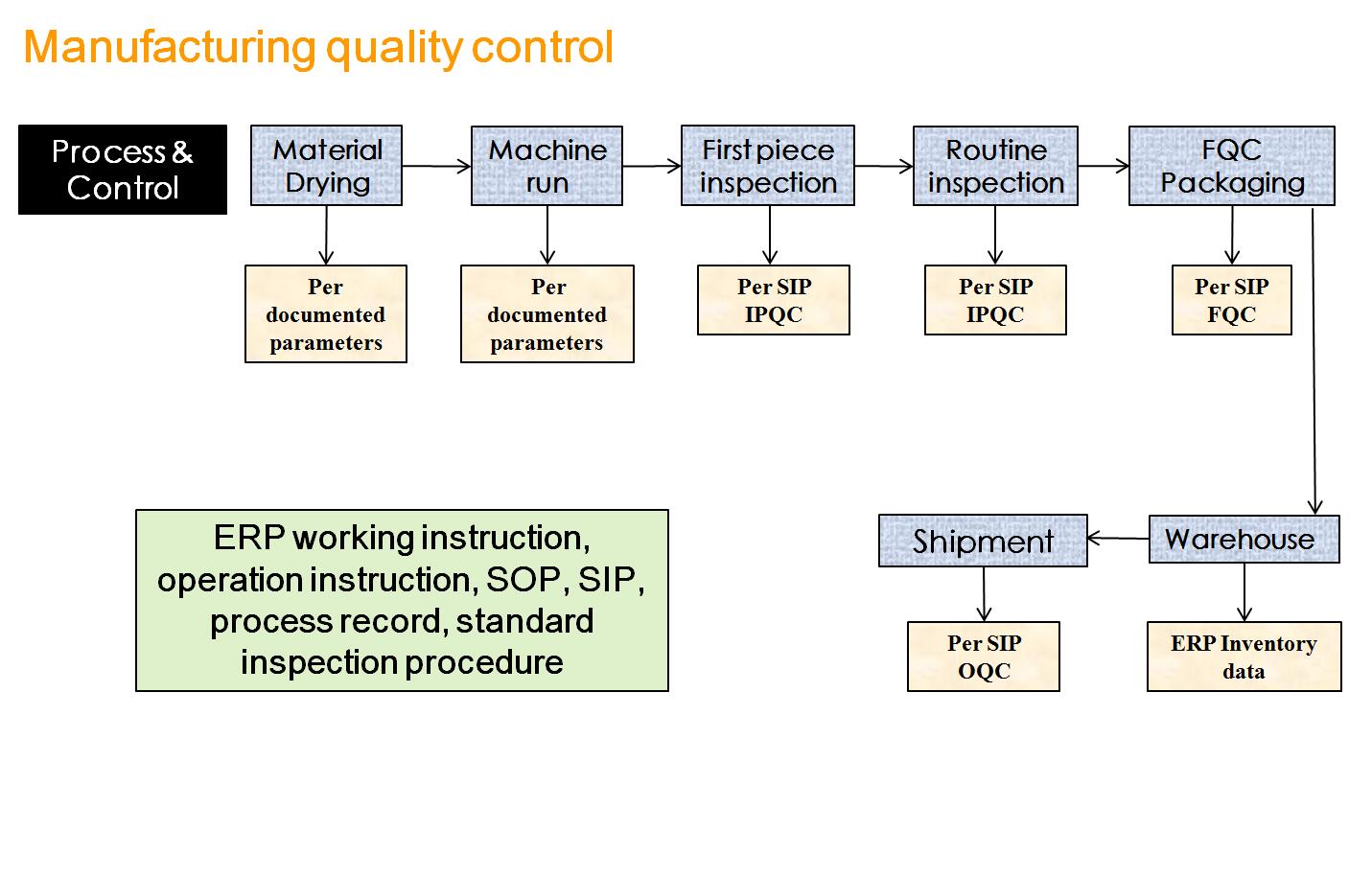

Injection Plastic Part Manufacturing Quality Control